- Phone Number

- +91-750 888 3687

- 114, Green Field,

- Near Pakhowal Road, Ludhiana

- Email Address

- snrreclamations@gmail.com

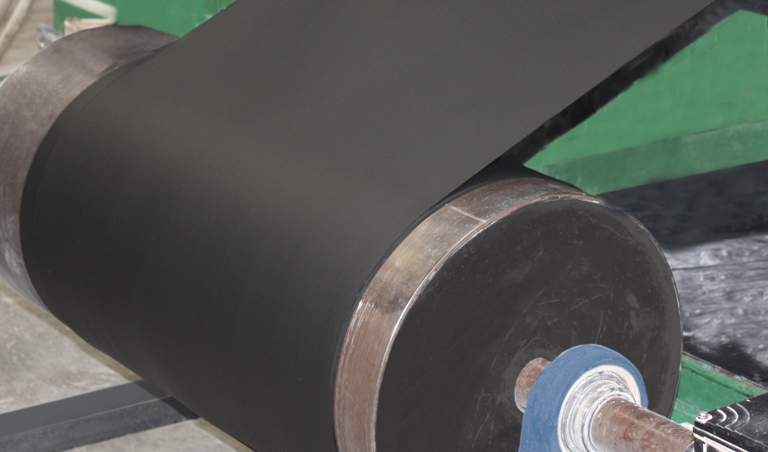

SNR produces Butyl Reclaim Rubber from old used scrape of Butyl Tube with well equipped production machinery & Modern Laboratory.

| Product | Grade | Description | Application |

| Butyl Reclaim Rubber | DE Butyl 90 | Butyl Automotive Tubes |

|

| TECHNICAL DATA | TEST METHOD | DE BUTYL 90 |

| ACETONE EXTRACT (%) | ASTM D 297-18 | 9 ± 3 |

| ASH CONTENT (%) | ASTM D 297-18 | 5 ± 3 |

| CARBON BLACK (%) | ASTM E1131 | 32 ± 4 |

| VOLATILE MATTER (%) | --- | 1.0(Max) |

| RHC (%) | ASTM E1131 | 50(Min) |

| TECHNICAL DATA | TEST METHOD | DE BUTYL 90 |

| Specific Gravity (gm / cc) | ASTM D 297-18 | 1.14 ± 0.02 |

| Tensile Strength (MPA) | ASTM D 412 | 85 (Min) MPA |

| Elongation (%) | ASTM D 412 | 500 Min. |

| Mooney Viscosity (1+4)@100°c) | ASTM D 1646 | 40 - 55 |

| Hardness at Shore "A" | ASTM D 2240 | 51 ± 5 |